Winter can take a toll on fueling equipment, from harsh weather conditions to increased wear and tear. Ice, snow, and freezing temperatures can cause seals to crack, filters to clog, and equipment to degrade. Spring is the time to assess potential damage and perform necessary repairs before the busy summer driving season begins. A proactive approach not only extends the lifespan of your equipment but also prevents costly emergency repairs down the line.

1. Fuel Dispenser Tune-Up

Fuel dispensers are the heart of any gas station and keeping them in peak condition ensures accurate fueling and customer satisfaction. Inspect hoses, nozzles, and breakaways for any damage or leaks. Look for cracks in the hoses caused by winter weather and replace any worn-out parts. Also, clean and calibrate dispensers to maintain fuel accuracy and compliance with regulatory standards.

2. Pump & Motor Inspection

Fuel pumps work tirelessly to move fuel from underground tanks to the dispensers. Spring is an ideal time to check for any irregularities in pump operation. Listen for unusual noises, check motor function, and verify that the flow rate is consistent. If you notice slow dispensing speeds, it may be time for a deeper service or even a replacement.

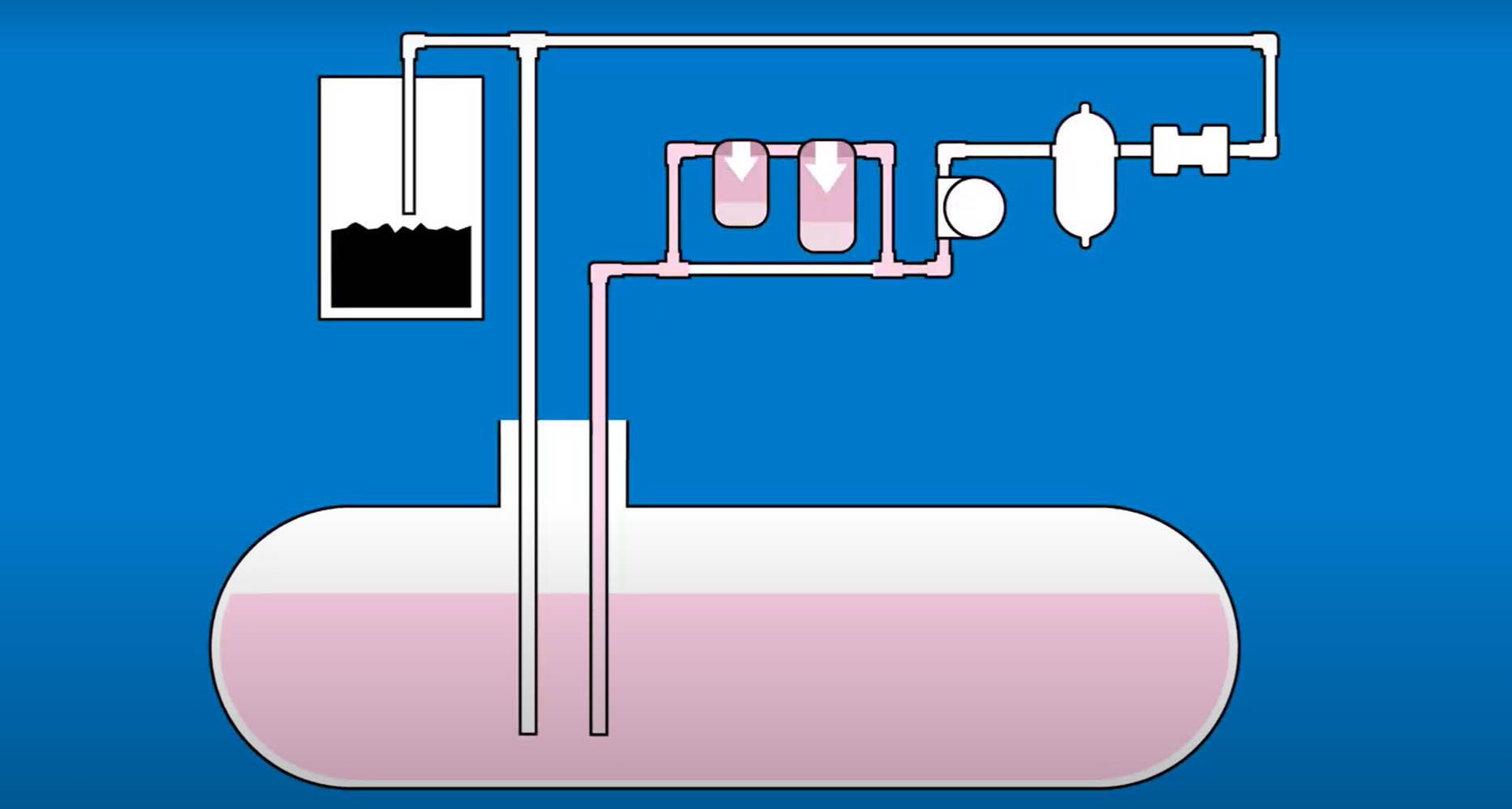

3. Tank Cleaning & Filter Replacement

Over time, sediment, water, and microbial growth can accumulate in underground and above-ground fuel storage tanks. This buildup can lead to clogged filters, poor fuel quality, and potential equipment failure. Spring is the best time for tank cleaning, in addition to replacing fuel filters to ensure smooth operation. Regular filter changes help prevent contamination and protect both your equipment and your customers’ vehicles.

4. Compliance & Safety Inspections

Regulatory compliance should always be top of mind for fueling operations. An annual inspection can help identify potential issues before they become major problems. Check for proper labeling, ensure emergency shutoff systems are functioning, and verify that fire suppression systems are in working order.

5. Canopy, Signage & Lighting Refresh

Beyond mechanical maintenance, spring is also an excellent time to enhance the overall look and feel of your fueling station. Inspect canopy structures for wear and tear, update signage, and replace any dim or non-functioning lights to ensure your site is well-lit and welcoming to customers.

Stay Ahead of Equipment Failures

Preventive maintenance isn’t just about keeping things clean—it’s about preventing breakdowns before they happen. Scheduling routine inspections and servicing equipment on a seasonal basis minimizes downtime, reduces costly emergency repairs, and enhances overall efficiency.

At Eaton Sales & Service, our expert technicians are ready to help you tackle spring maintenance checklists. Whether you need pump repairs, filter replacements, tank cleaning, or compliance inspections, we’ve got you covered. Don’t wait until a minor issue becomes a major disruption—schedule your maintenance today and keep your fueling operation running smoothly all year long.